Custom Designed Solutions

1-800-593-5326

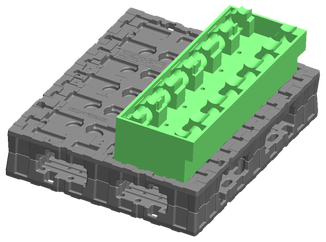

Jeco Plastics manufacturers a broad variety of custom made pallets. Including ribbed, flat, stackable, and other special configurations.

Most Jeco custom made pallets can be manufactured on short notice. Either using existing tooling or designing for it.

Jeco custom plastic pallets are also available for use in handling paper and board roll stock. Our custom plastic pallets have been tested extensively and are known for strength and the ability to handle large, heavy rolls and protect them from damage in storage.

Need a special configuration?

Jeco often can make minor changes to existing tools.

A manufacturer specified a work-in-process pallet which would be completely recyclable yet perform as well as existing steel pallets. After an exhaustive development and testing program, Jeco Plastics developed a pallet which exceeded specifications within the required weight and price parameters.

A North American manufacturer of over-the-road trailers required an extremely rotomolded plastic pallet to transport panels for final assembly. Requirements included 15-year life, low cost, high strength and weight bearing capability, and the ability to protect the panels from scratching and abrasion in transit. Because panels were to be stored outside, the pallets needed to be impervious to extreme temperatures and weather. Metal pallets were unacceptable because of static charge buildup. Jeco Plastics developed and produced a 115 x 54 inch (292 x 137 centimeter) pallet which met every aspect of the specifications.

A Jeco Plastics specialty is manufacturing rotomolded plastic pallets for large, extremely heavy rolls, for use in paper manufacturing and metal rolling mills. Typical of these is this stackable pallet, measuring 54 x 110 x 16 inches (137 x 279 x41 centimeters), capable of supporting a 28,000-pound (12,600 kilogram) load without deflection. The pallet includes steel inserts which distribute the load and provide extra strength.

Jeco Plastic Products has developed multi-sided pallets to enable storing extremely heavy round loads. In one particular design, we found it supported a 10,000-pound (4,500-kilogram) roll of paper stored on end, without deflection or damage to the fragile paper. Our products are stronger than expectations. In a copper wire manufacturing operation, that pallet design supports 22,000 pounds (9,900 kilograms), and withstands 130°F (54°C), 11,000-pound (4,950-kilogram) coils dropped from 6 feet (1.8 meters). The pallet is forklift accessible from any direction.

Jeco Plastics has extensive experience designing and manufacturing hygienic plastic pallets and containers for food processing and pharmaceutical applications. We have hygienic plastic pallets designed for cold room use. We can create food-grade use mold pallets using a specially formulated, FDA-approved resin. Our hygienic plastic pallets are resistant to liquids, smooth-surfaced, and easy to clean for sanitation.

When not in use, these Jeco pallets require minimum storage space. Logistics pallets such as these are designed for maximum stackability and ease of cleaning in a special environment.

These proprietary Jeco Plastics pallets are designed with a lipped top, preventing loads from slipping beyond the edge. Special designs like these are readily executed in plastic, but very expensive and difficult to produce in materials such as steel or wood.

This symmetrical Jeco Plastic’s pallet design is never inverted and always ready to use.

Designed with runners, rather than feet, this specialty Jeco Plastics pallet was designed to automatically receive stacked products as it comes from the production machine. It can be strengthened with steel if loads are great.